How Cannabis Automation Can Streamline Every Stage of Your Production Process

In today’s world, automation is the key to efficiency for most industries. In cannabis, it’s not just beneficial; it’s crucial in the competitive market. For companies looking to scale or seeking to thrive (not just survive!), building automation into their processes is often make or break.

So, if you’re a newly licensed, pre-op brand…learning how cannabis automation can boost operations from the start is an immediate advantage. If you’re already operating, then you know all about the challenges above all too well.

Regardless of where you are in your company’s growth stage, the automation experts at Hefestus have put together the ultimate guide to how it can help. Here, we’ll cover all the basics you need to know about challenges in cannabis production and how cannabis packaging automation is just the start of facility efficiency while sharing time-cost savings, real-time case studies, and more to drive home the importance of the topic for your bottom line.

Keep reading to dive deep into the world of cannabis automation (and learn how our Industrial joint rolling machines are designed to help you scale).

Challenges in Cannabis Production

It’s not just an emerging product you’ll have to master producing or an ever-evolving industry you’ll need to adapt to when working in cannabis. There are ever-evolving regulations you must navigate and adhere to, too. Between compliance and other challenges inherent to the industry, operations can be nearly impossible to scale.

Of course, what helps is understanding the common challenges and overcoming them to grow. Before we learn more about how cannabis automation supports operation excellence overall, let’s first understand the unique challenges in cannabis production it can also help overcome.

- Labor inefficiencies: For most facilities, cannabis production relies heavily on human or manual labor. From trimming and weighing to filling and packaging, manual labor can slow down overall throughput and create inconsistencies across batches.

- Product inconsistency: Consistency is king for cannabis consumers, yet maintaining it can be a daily battle. Variability in hand trimming, measuring, or filling processes often results in products that differ in size, potency, or appearance. This not only affects customer satisfaction and brand trust but can also raise red flags in compliance audits.

- Compliance risks: Speaking of compliance…in the highly regulated cannabis industry, one minor error can cost operations in fines or fees or, even worse, a halt in production. When using human labor, human error risks increase, which often leads to labeling errors, incorrect dosing, or non-compliant packaging without proper oversight.

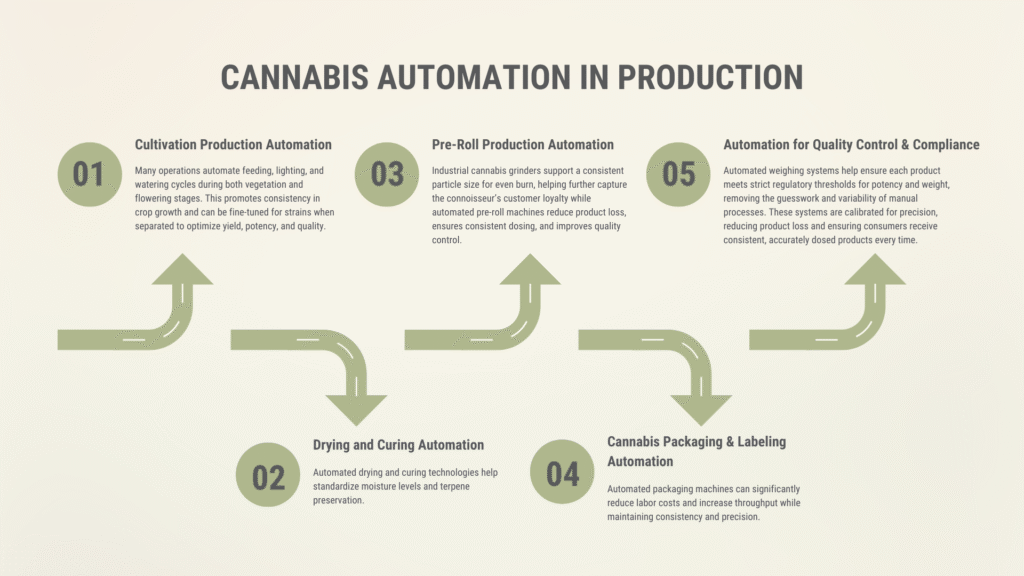

Cannabis Automation in Production

Today’s cannabis operators are turning to cannabis automation to overcome the industry’s common challenges, improve morale, and scale exponentially. Next, let’s explore how that looks at different stages in production.

Early-Stage Production Automation Cultivation, Drying & Curing

Implementing automation at every stage or step possible streamlines overall operations. While in early-stage production, it’s harder to automate tasks like cloning or transplanting, there are innovative methods that can help reduce manual labor and increase consistency across the board, when it comes to plant health.

For instance, many operations automate feeding, lighting, and watering cycles during both vegetation and flowering stages. This promotes consistency in crop growth and can be fine-tuned for strains when separated to optimize yield, potency, and quality. Even more, these automated systems often track data for real-time insights and analysis to make better-informed decisions.

Once harvested, automated drying and curing technologies help standardize moisture levels and terpene preservation—two key elements in product quality. These systems reduce the risk of over- or under-drying, which can lead to mold, harsh flavor, or cannabinoid degradation.

How Automation Enhances Pre-Roll Production

The labor-intensive processes necessary for cannabis manufacturing only continue post-harvesting—especially for those producing pre-rolls. Pre-roll production is one of the most labor-intensive processes in cannabis manufacturing when done by hand. Not surprisingly, manual rolling slows output and often leads to weight, density, and burn quality inconsistencies.

To start, industrial cannabis grinders support a consistent particle size for even burn, helping further capture the connoisseur’s customer loyalty. Cone fillers and industrial joint rolling machines are additional cannabis automation tools that streamline operations while also supporting product consistency and quality.

These systems skip the manual packing and twisting process for workers and produce hundreds to thousands of joints per hour. Not to mention, automated pre-roll machines are also far more accurate than manual teams, which reduces product loss, ensures consistent dosing, and improves quality control.

Cannabis Packaging & Labeling with Automation

Again, automation continues to benefit cannabis production as the product moves into the packaging and labeling stage. Automated cannabis packaging solutions are crucial to speeding up the process of packaging and labeling hundreds, if not thousands, of products and keeping them compliant, too.

Automated packaging machines can significantly reduce labor costs and increase throughput while maintaining consistency and precision. From filling jars to bagging flower these machines ensure every product is packaged to spec, minimizing waste and human error, which can be costly for operators.

Advanced labeling and tracking solutions support compliance assurance by applying accurate dosing, ingredient, and batch information required by METRC or other regulatory systems directly onto the product packaging. This ensures every item is traceable and compliant with evolving state and federal regulations while improving operational efficiency and brand credibility.

Automation for Quality Control & Compliance

Finally, using cannabis automation compliance tools is essential for both remaining compliant and maintaining quality. For instance, automated weighing systems help ensure each product meets strict regulatory thresholds for potency and weight, removing the guesswork and variability of manual processes. These systems are calibrated for precision, reducing product loss and ensuring consumers receive consistent, accurately dosed products every time.

As for quality, robotic systems minimize human handling, which reduces the risk of contamination and cross-contact between batches. Even minor missteps can result in costly recalls or failed inspections in highly regulated environments.

That’s why many facilities now integrate automated track-and-trace technologies to capture real-time data, manage inventory, and create transparent audit trails. Together, these automation tools make it easier to meet legal standards while maintaining a clean, consistent, and compliant operation from start to finish.

Time and Cost-Saving Benefits of Automation

Implementing cannabis automation into your operations isn’t just about keeping up with the trends. It’s about building a smarter, more scaleable operation. By reducing manual labor and streamlining repetitive tasks, automation allows producers to reinvest time and resources into higher-value areas like product development, marketing, and compliance strategy.

No matter the stage of production you’re automating – the time and cost savings add up quickly. Here are a few of the most impactful ways automation drives efficiency:

- Reduced labor costs: Automated equipment performs tasks faster and with fewer workers.

- Faster production cycles: Machines can operate continuously with minimal downtime.

- Less product waste: Precision dosing and packaging minimize human error and material loss.

- Lower compliance risk: Standardized processes reduce the chance of labeling or dosage mistakes.

- Improved scalability: Automation supports growth without the need for proportionate increases in staffing or space.

Real-World Case Studies

Of course, understanding and knowing more about cannabis automation is one thing. Seeing its results in the real world is another.

For instance, Forbidden Farms in Washington transitioned from manual pre-roll production to utilizing Hefestus’ AuraX machines. This shift resulted in a 90% reduction in labor costs and increased output from approximately 100–120 joints per hour to over 1,000, significantly improving consistency and reducing compliance risks.

Similarly, VASCO Cannabis in Quebec implemented automation tools to streamline inventory and quality control processes. This integration saved the company over $100,000 annually in labor costs and reduced the time required for compliance reporting from hours to mere minutes.

These real-time cases represent the importance of seeking automation solutions that align with supporting specific operational needs. Keep in mind that successful implementation goes beyond investing in reliable equipment. It also entails effectively training staff, and choosing partners that offer equally reliable support and adaptability.

By doing so, cannabis businesses can achieve scalable growth, maintain product quality, and navigate the industry’s complex regulatory landscape more efficiently.

Why Automation is the Future of Cannabis Production

If AI and automation are the future in most industries and spaces…why not cannabis production? The burgeoning industry is prime for innovation in general, and its equipment is ever-improving with the inclusion of more and more manufacturers into the space (like Hefestus!).

In cannabis, there’s an emerging labor trend in which workers strive for more meaning in every position, as shown by high turnover. This is creating a demand for cannabis automation to take mindless jobs, such as filling or packaging pre-rolls, and allowing the human workforce to explore other, more fulfilling jobs across the industry.

Ready to Revolutionize Your Cannabis Production?

Energized for the next step in efficiency after this read? It starts with revolutionizing your facility’s cannabis production.

In this guide, you learned about how cannabis automation can streamline every stage of the production process – while protecting your operation’s bottom line. Take this as a sign to invest in your operational excellence to gain a competitive advantage.

Before you go, you should also learn more about Hefestus, a leading provider of cannabis automation solutions, including industrial joint rolling machines and beyond. Explore Hefestus-Tech’s state-of-the-art pre-roll machines, packaging solutions, and more, now.